We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. Hit the link at the bottom of the post to submit your own question.

Welcome back to the Bikerumor Ask A Stupid Question Series. This week, we’re pivoting the conversation to bearings, specifically needle bearings, and their useful applications in bicycle componentry. You wanted to know what advantages, if any, needle bearings (aka roller bearings) offer over your regular cartridge bearing or plastic bush.

To answer your question in a comprehensive fashion, we’ve consulted a bunch of brands who utilize needle bearings at a number of different points on the mountain bike, from pedal axles, to frame pivots, to shock eyelets. Your expert contributors are as follows:

- Jamie Duncan, Design Engineer at PINND Pedals

- Matt Harvey, Co-Founder of Enduro Bearings

- Tripp Hurt (Partner/Engineer) and Craig Payne (Founder) of Hustle Bike Labs

- Chris Streeter, Owner of Real World Cycling (Enduro Fork Seals)

PINND: Why do our PINND CS2 pedals use needle bearings? We opted for a needle bearing for a few reasons. The 1st being that the main cause of pedal failure is due to internal seizure and this is usually down to the seal not working properly at the crank side. This is due to the bush wearing and allowing axial play on the axle which will mean the seal can’t work due to the errant movement.

No matter how fancy the bush is, at the end of the day, it’s plastic and therefore the weakest component in the pedal assembly. PINND designed this out and introduced a needle bearing in its place, which removes the play allowing the seal to work as it should. The sacrifice is a couple of millimetres in platform thickness and it costs a little more but we think the benefits are worth the sacrifice. No bearing will last forever, but they will outlive a plastic bush by a very, very long time!

Enduro Bearings: What is the advantage of a needle bearing over regular ball bearings or bushings? Well, needle bearings generally have a much higher static load rating than the same sized ball bearing. Needle bearings generally require higher tolerances of alignment, press fit and mating parts in order to work correctly. They cannot account for thrust loads as a single ball bearing can so sometimes you need mating thrust washers, bushings, or even ball bearings next to them to account for that.

They can work well on shock mounts where everything is in alignment without high axial loads (twisting, misalignment). They must be fitted quite tightly to avoid “knocking”. In our 15 year experience with supplying them for this duty, we have encountered very few problems with them. In Enduro Bearings design, we also supply them with separate seals on each side to keep them clean and retain the grease.

Do they hold up in wet and muddy trail conditions and how much reduced friction do they actually offer? If sealed properly, they will. There are integrated sealed needle bearings, however the needles in this case get shorter and the load rating comes down. The seals inside needle bearings are moderately effective, external seals on the sides work much better.

As for the statement relating to frame pivots… Multi linkage frame pivots generally have high axial loads (which is multi load directions, a side load is considered thrust loads, and Radial load is straight down perpendicular) where uneven side loads and twisting occur. Needle bearings need to work in an environment of good alignment so that the edge of the needle is not taking all of the load and “pinching”.

Max type ball bearings are very good at taking not only radial loads, but axial loads. This is in every direction. Ball bearings can account for the misalignment of 8 or 12 pivot points in many modern frames, where perfect tolerances due to welding or carbon layup are not possible.

Hustle Bike Labs: Needle bearings have larger bearing surfaces, known as the “needles”, so they are able to accommodate higher loads than a regular ball bearing and at a lower friction. Bushings are technically a type of bearing, but think of them more as a sleeve. They are oftentimes made of plastics and represent a cheaper option as they should theoretically fail more often than a steel bearing.

If you look at the historical uses in MTB: MRP used to have a kit to replace the bushings on the earlier models of Specialized FSR with needle bearings, Devinci used them in the early 2000s in the main pivot of their frames, and dirt bike companies have used needle bearings in their pivots due to the extremely high loads that exist in this application (high speeds and jumping).

However, I think a decision on “is it worth it”, should be more made upon the quality of the bearing than if it is needle versus ball bearing or even bushing. Friction ultimately will be dictated more by the quality of the bearing (the tolerance the machine is able to hit is really important here), materials it is made of (ceramic has a lower coefficient of friction than steel, and always choose high quality stainless steel), and oftentimes the other parts of the system (i.e. shielded versus sealed).

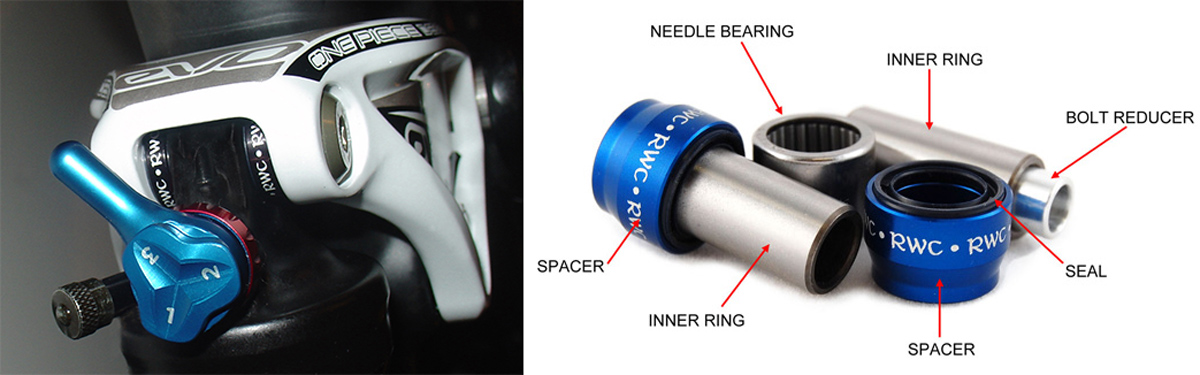

Real World Cycling: The main advantage of a needle bearing over a bushing is the decrease in friction, which is dramatic. In direct relation to the reduction of friction is the increased longevity of a needle bearing – especially in high rotation applications.

The main advantage of a needle bearing over a standard cartridge bearing is that greater load strength is provided in a much smaller package. Needle bearings can have up to 8 times the load-carrying capacity per given mass than other bearing types. If you have plenty of room to work with, this may not be an issue, but the weight difference is also significant.

Pedal axles are a perfect example of needing a strong and durable bearing in a compact space. Of course, proper engineering to get the right size and for proper sealing is essential, but in theory, for pedal applications, they make more sense than cartridge bearings. This doesn’t mean that doubling up smaller cartridge bearings or other innovative uses of standard cartridges can’t be successfully implemented for pedals (or a combination of bearing types used).

For upgrading standard rear shock eyelet bushings, I will let our many satisfied customers testify to the improved performance. One forum thread has over 34 pages of posts about our kits and is entitled “Real World Cycling Shock Needle Bearing Kit is Awesome.”

I will say that, where there is no rotation inside the shock eyelet, NO, it is not worth it. Often, at least one end of the shock remains in a fixed position relative to the frame. BUT, where there is rotation inside the eyelet, the improvement in responsiveness is quite remarkable, and a bargain for those obsessed with performance. We are happy to give honest assessments on a frame-by-frame basis as to whether or not your frame would benefit.

Do they hold up in wet and muddy trail conditions? Most hardened bearing steels are susceptible to corrosion. Different bearing materials, sealing options (internal to the bearing and external to the bearing) can be implemented by the engineer designing the component or frame. There is no inherent anti-corrosion benefit to one type of bearing over another independent of the actual bearing materials and seal designs. Speaking specifically about our Shock Needle Bearing Kits, the spacers include high quality seals, but frequent wet and muddy riding may require more frequent lubing of the bearing.

How much reduced friction do they actually offer? Compared to a bushing, in a bicycle frame pivot application (high load, low rotation) there is no comparison. Several manufacturers have made expensive transitions to various bushings for their frame pivots, including some elaborate angular contact bushing designs. With just a few exceptions, they have all come back to metal bearings of some sort. Regarding those exceptions, we get requests from customers for needle bearings to replace those places on the frame that have bushings.

One of the reasons we launched the Shock Needle Bearing Kit is because factory bushing systems were so bad that the shock hardware was wearing away parts of the frame (instead of rotating inside the shock eyelet).

Finally, with reference to frame pivots, needle bearings have been used in frame pivots. However, they are more difficult to properly integrate with the frame. Among other factors, manufacturers have to balance performance, price, and amount of labor to assemble when making frame design choices. Cartridge bearings come as a complete unit with outer race (or “ring”), inner race (or “ring”), ball bearings, and seals. The needle bearings have a separate axle (inner ring) that must also be made of the hardened bearing steel. The axle needs to fit properly inside the rollers, which is not easy when the bearing “cup” containing the rollers gets compressed in the frame. For mass production, cartridge bearings are easier to deal with.

Got a question of your own? Click here to use the Ask A Stupid Question form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!